The roadway conundrum

Originally constructed in 1905 by the Territorial Legislative Assembly, and containing segments of the old Rte. 26 from Deming to Nutt and a stretch from Nutt to Hatch (which were originally Rte. 27), Rte. 26 in New Mexico was shown, in a map dated 1927, as a “first class” road between Deming and Hillsboro constructed primarily of oil and concrete segments. This roadway was first paved with modern-day asphalt in the 1950s. Its proximity to the Mexican border makes this route popular for north-south freight traffic.

S.R. 26 is a rural road that is tucked away in the rolling terrain of the southwestern part of New Mexico. It is one of those rural roads that is heavily used by a diverse group of users, from tourists to “Sunday drivers” to freight haulers. The road itself is a 47-mile-long, paved two-lane state highway that traverses three counties: Sierra, Luna and Doña Ana. The roadway is a west-east connection, but in reality, it travels southwest-northeast, largely following the main trunk of the ATSF railroad.

The beginning or western end of the route is in Deming, a community mostly known for its agriculture. Deming is within 35 miles of the Mexican land port of entry in Columbus. Mid-route lies the Las Uvas Valley, better known as the Valley of the Grapes. Within this valley is the region’s largest dairy. This fertile valley also produces much of the livestock feed for the dairy, as well as produce such as chiles, tomatoes, potatoes and watermelons. The end of the route or eastern end is the Village of Hatch. Hatch is globally known as the “Chile Capital of the World.” Chiles locally grown in Hatch are trademarked as such.

A 2009 Roadtec D Shuttle Buggy was part of the paving train on the Rte. 26 pavement rehabilitation project

Rte. 26 is a shortcut between I-25 and I-10 and is functionally classified as a minor arterial. With an AADT of 7,800 vehicles with 27% heavy commercial use, this shortcut is approximately 75 miles shorter and approximately 6 minutes longer to drive than the alternate route of using an all-interstate route.

Roadway construction of this route was most recently done in 2007; the western half (25 miles) of the route was rehabilitated with 4 in. of cold in-situ recycled material capped with 2.5 in. of Superpave III, and a 5/8-in. friction course. In 2008, the eastern half (20 miles) of this roadway received a rehabilitation that included 4 in. of cold milling capped with 6 in. of Superpave III and a 5/8-in. friction course. The eastern half of this route has not shown signs of deterioration and is considered in good condition.

As standard practice, the New Mexico Department of Transportation (NMDOT) provided a Pavement Condition and Structural Design Recommendations Report for the first 25 miles. This report represents current pavement and surface conditions, field core data and section recommendations. The current pavement distresses are represented by the following indices: Pavement Condition Rating (PCR), International Roughness Index (IRI), rutting, and fatigue cracking.

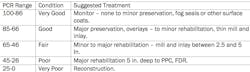

The PCR is a composite index that was developed specifically for New Mexico and is based on 80% pavement distress and 20% roughness. The PCR is described using a 0-100 scale, which is the most common state practice in presenting the current condition of the roadway, as shown:

In general for this project, the PCR ranged from fair to good, except with a short segment of 6 miles that ranged from poor to fair (cold in-situ layer). The main reason for the low PCR is fatigue cracking which covered 20–40% of the total section.

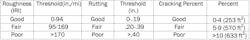

International Roughness Index, rutting, and fatigue are the other factors represented in the report. The following table shows the limits set forth by FHWA for all non-urban pavement sections:

The IRI for this project varies from a rating of fair to poor. This rating can be attributed to cracking. The average rutting varies from fair to good. The area of cracking based on square feet generally varies from fair to poor.

Field cores were advanced throughout the project in spacing intervals of approximately 1 mile. The cores within the low PCR (6-mile range) were found to have moisture-induced (asphalt) stripped layers, top-down cracking and general de-bonding. The pavement condition data confirms the presence of deteriorated pavement as evidenced by moderately high roughness (IRI) and fatigue. It appears that much of the delamination, stripping and fatigue may be the result of the cold in-place recycling layer constructed in 2007.

The recommendation ultimately was a major rehabilitation treatment between 2.5-5 in. of mill and inlay. The data from the cores and the report confirmed the root cause was within the cold in-place recycled layer. In 2016, NMDOT awarded Mountain States Constructors Inc. with a 145 working day contract at $7,247,670.10. The scope of the project was pavement rehabilitation that included milling the top 3 in. of asphalt and inlaying with 3 in. of Superpave III. A roadside barrier upgrade was included in the scope of the project. The project termini was from mile post 0 in Deming to mile post 25 near Nutt, or the western half of the route.

Mountain States Constructors was able to complete this roadway rehabilitation within 87 working days. One lift of hot-mix Superpave III using a binder grade of PG 70-22 at 5.1% oil content was used. Total tonnage placed was 58,851 tons of which 15% by weight included recycled asphalt pavement (RAP). NMDOT specifications allow a contractor to use up to a maximum of 35% RAP, but use of greater than 15% requires the contractor to make adjustments to the grade of asphalt binder. The contractor had a 5-mile work zone for all paving operations with a pilot car setup, because S.R. 26 is a two-way road with heavy traffic at all times.

The smoothness on the final product for Rte. 26 showed an average IRI in the low 30s.

The equipment employed by Mountain States Constructors for milling was a 2009 Cat PM201 Milling Machine, a 2011 W2200 Wirtgen Milling Machine and a 1999 W5 Wirtgen Milling Machine. The hot-mix plant was a 2009 CMI E3 Asphalt Continuous Drum counter-flow mixer plant. A pair of 2005 John Deere 210 LE grading tractors and an ICC Truck Mounted Profilograph prepared the site, and pavement placement utilized a 2008 Cat 1055 paver, a 2008 Cat Windrow Elevator, a 2009 Roadtec D Shuttle Buggy. Compaction was achieved with a series of 2016 Hamm HD140 VV-HR Rollers and a 1997 Ingersoll Rand DD 110 Finish Roller.

The end result was excellent, as the profilograph results showed an average IRI in the low 30s.

While NMDOT considered other alternatives for this project, including full-depth reconstruction, stone matrix asphalt, full-depth reclamation and pavement preservation, the overall project cost was, as it often is, a major determining factor for the scope of the work. A benefit cost analysis was completed to assist with the decision. NMDOT also relied on the results obtained from the core data, which showed failure within the top 4 in. of the existing pavement. The cost of reconstruction was determined to be $1.2 million per lane-mile. Full-depth reclamation was estimated at $390,000 per lane-mile, while the pavement rehabilitation that was ultimately chosen was completed at $145,000 per lane-mile, resulting in an overall project cost savings of approximately $23 million for the entire 47-mile stretch.