Thirty years in the making, a tollway through an environmentally sensitive area relieves congestion

The area south of Austin, Texas—near Buda—needed a faster route to reach State Loop 1 and downtown Austin.

Drivers were using local roads as commuter corridors to access the major highways, which became increasingly congested. Concerned residents expressed their worry about the cut-through traffic in their neighborhoods and the resulting inability to safely exit their area. The resolution came in the form of State Highway 45 SW, an innovative 3.6-mile, four-lane toll road and 4.5-mile pedestrian/bike path, the idea for which began over 30 years ago in 1989, with the approval of the Final Environmental Impact Statement.

A project of the Central Texas Regional Mobility Authority, this highway was more of a hot topic than most roadway projects, due to the fact that the majority of the project is located in the Edwards Aquifer Recharge Zone. The aquifer serves as a drinking water source for millions of people in the surrounding communities. Moreover, the geographical formations that make up the aquifer serve as a habitat to several rare and threatened species. Thus, the highway was constructed with the environment as a top priority from inception to project completion. This theme was established early in design and resulted in countless hours of collaboration among local agencies and shareholders through the establishment of an interagency Technical Work Group (TWG). This group included the Mobility Authority, the Texas DOT (TxDOT), the City of Austin Watershed Protection Department, Barton Springs Edwards Aquifer Conservation District, and Travis and Hays counties. The TWG established the foundation of the project’s best management practices (BMP). When McCarthy Building Companies began construction, they worked with the clear understanding of the environmental responsibilities and the Mobility Authority’s desire for a high-quality product.

Environment first

The sensitive environmental needs of this project presented unique challenges requiring extensive planning. The project was developed as a transportation-conservation landscape. This means that one-third, or 95 acres, of the total right-of-way was excluded from the construction footprint to conserve native woodland and provide preservation and protection to 20 known Edwards Aquifer recharge features, such as caves, sinkholes, and solution cavities.

To maintain as much of the natural areas as possible, large portions of the project were identified as construction exclusion zones (CEZs), making for a tight work area. An even larger area—60% of the work zone—had a Prohibited Activity Layout (PAL). These are areas where construction was to take place but prohibited staging of stockpiles and construction materials; the parking of vehicles and equipment except when actively working; fueling equipment; maintaining equipment; or concrete washouts. On many occasions, track equipment, including cranes, were moved over half a mile to be fueled and maintained and stored at the end of a shift.

Furthermore, to minimize the impact to the extensive karst features—areas for water to enter the aquifer—rather than going downward, the design and construction process undertook “upward construction.” Approximately 90% of the project was constructed on fill, greatly reducing the need for excavation that could potentially disturb the aquifer and the karst features.

Additionally, the Texas Commission on Environmental Quality (TCEQ) requires projects over the Edwards Aquifer Recharge Zone to remove 80% of the increase in total suspended solids (TSS). The SH 45 SW project team achieved a TSS removal rate of 98% over the aquifer and 92% over the entire project.

Asphalt and Innovative Paving Techniques

Permeable friction course (PFC) asphalt was used on SH 45 SW. The PFC provides an initial filtration of water prior to it entering the storm drain system and making its way to the eight holding ponds. The project consisted of 4 in. of Type B hot mix asphalt, 2 in. of Type C hot mix asphalt, and 1.5 in. PFC. Three out of the four mix designs used on the project had a good history and performance on TxDOT projects. For the PFC-F design, multiple blends were used in the lab to come up with the best mix that met all the performance requirements. The asphalt work was completed by Austin Materials and the equipment they used consisted of Cat AP1055F and AP1000F pavers, Roadtec SB-2500E Shuttle Buggy, Cat and Volvo Steel Wheel Asphalt compactors, and BOMAG pneumatic compactors.

The compacting pattern for all dense graded mixes and the initial rolling pattern was established with two vibratory passes and one static pass with the breakdown roller. This was done using the machine’s high-amplitude/low-frequency settings. After the initial breakdown passes, 10-15 pneumatic passes and two static passes with the finish double-drum roller were used. All machines were kept close to the paver to stay in the appropriate temperature range to help maximize compaction. Austin Materials’ on-site 1-B would then utilize a TransTech gauge to check compaction after the breakdown and finish passes. After taking reference cores to verify the readings, any necessary changes were made to the rolling pattern.

Pavement played a vital role to the success of the project and quality in construction was of utmost importance to the Mobility Authority, so the team put the following specifications and innovations in place to ensure the best possible delivery of the project:

Ride Quality Innovation: The project specifications required the contractor to perform an International Roughness Index (IRI) test on Type C binder course prior to placement of the PFC surface course. IRI values greater than 86 were remedied by using diamond grinding, and IRI values between 70 and 86 were remedied on a case-by-case basis as decided by McCarthy and Austin Materials. A reasonable ride quality on the binder course was first achieved to ensure the road also attained the specified ride quality on the surface course. If the IRI value was not achieved on the surface PFC course, then it required removal and replacement, which in turn would create additional undesirable transverse joints that would negatively affect the overall ride quality. The project had a max 70 IRI requirement for both the mainlanes and frontage roads. SH 45 SW achieved an average IRI of 46 on mainlanes and 61 for frontage roads. The frontage road paving was an overlay on connecting facilities, unlike the mainlanes, which was new construction.

Quality Paving Joints: Longitudinal joints of 2 in. or greater thickness were constructed with a taper in the form of 3H:1V notched wedge joint. While standard practice is to form a vertical joint, the notched wedge joint provided several benefits including extra safety for vehicles to traverse lanes that were under construction and improved density along the longitudinal joint, which in effect will lead to longer pavement life. The base course Type B and binder course Type C hot mix utilized the notched wedge joint since they were 4 in. and 2 in. thick, respectively.

Innovative Placement Procedures: For the PFC mixes, the goal was to not have the rollers stop at all during the shift. The paver was allowed several hundred feet ahead before compaction with two double-drum rollers began. The two double-drum rollers were used in echelon to cover the entire paving width. If the rollers caught up to the paver, they were pulled off the PFC and onto asphalt that had already been paved. Periodically, one of the double drum rollers would drop back to eliminate any aesthetic longitudinal seams created by the rollers.

At places such as gores and variable-width shoulders where surface courses are typically constructed by varying the width of the paver, the team decided to have Austin Materials place the PFC at a constant width and then mill out the excess after compaction. This construction process helped to avoid bumps and dips along the longitudinal joints that would need to be matched when paving the actual travel lanes. Additionally, it helped create straight longitudinal joints outside the wheel path and ultimately improved the final project ride quality, resulting in no removal/replacement of PFC. Due to the nature of open-graded PFC mix, it is difficult to achieve good compaction on a taper, which otherwise can easily ravel. Therefore, by having the full width to be paved, the team achieved desired compaction at areas where the width varied.

“This was by far one of the best projects for partnering at all levels,” said Lloyd Chance, Assistant Director of Engineering Construction, for the Central Texas Regional Mobility Authority. “The teams consistently came together on each of the challenging aspects of the project with a positive attitude and solutions to get the job done. The PFC paving was just one example of team partnership from the pre-pave meeting to the final IRI results.”

A winning finish

The team’s constant pursuit of quality asphalt pavement has been recognized by winning two awards for asphalt quality. The project won the Texas Asphalt Pavement Association (TxAPA) Quality Asphalt Pavement Award (Non-TxDOT) and a National Asphalt Pavement Association (NAPA) Quality in Construction Award.

“This project is a perfect example of both the owner and contractor being on the same page regarding the end results,” said Alex Flores, VP of Construction for Austin Materials. “Many times, it’s ‘just finish early’, but on this project the expectation was set that the goal was on time, but more importantly that it be an award-winning project. This mentality was carried by all parties and helped factor into decisions about project phasing and quality. For instance, we could cut up and phase the project in a way that might be more convenient, but then the road would have been patched together. Because the goal of quality was in mind, all parties decided that convenience would be second to quality. Thus, we were given the tools to provide a quality smooth paved final surface. Tools such as multiple lifts, opportunities to profile mill and level up, and to wait for all the areas to be done before we paved final surface.”

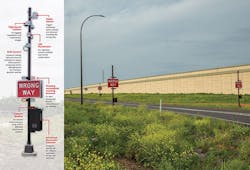

Despite a few construction and environmental challenges, the project was delivered 64 working days ahead of schedule and $3 million under the overall budget. Because of that the Mobility Authority was able to add additional desired amenities to the project without impacting the overall project schedule or going over budget. These desired amenities included monument signs, expanded kiosk signage, wayfinding poles, and additional informative signs throughout the shared-use path. State Highway 45 SW is an exemplary model for environmental commitment, multi-jurisdictional collaboration, and excellence in civil engineering design, construction, and technology.