Illinois Tollway continues to be a big asphalt player for contractors

The Illinois Tollway maintains and operates 294 miles of roadway on five tollways across 12 counties in Northern Illinois and serves more than 1.6 million vehicles each day.

The system serves three international airports, connects to the nation’s second-largest rail network, and strives to provide a safe and efficient system of highways to serve its customers. It is a nationwide leader in tolling technology and capital program development that serves as the backbone of the Chicagoland region.

Quietly, however, the Illinois Tollway has been serving as a testbed for engineers and industry leaders throughout its current 15-year, $14 billion Move Illinois Capital Program.

Illinois Tollway staff and leadership have embraced the philosophy that innovations can lead to cost savings and environmental stewardship while providing equal or improved pavement performance. With no federal or state funding, and resources independent from the Illinois DOT, the Illinois Tollway has leveraged its latitude for innovation by quickly taking advantage of new products and innovations aimed at testing and implementing product performance.

On multiple preservation and system-wide improvement projects in 2018, the Illinois Tollway provided contractors with a variety of choices for their asphalt mixture ingredients. Contractors had a wide range of tools to choose from including binder types, binder modifiers, rejuvenators, warm-mix asphalt technologies, increased asphalt binder replacement, and a wider range of permissible aggregates.

By giving options, contractors are able to select which materials and combinations are best for their plant, sources, and process. To ensure a quality end-product, the Illinois Tollway goes beyond standard method specifications and requires state-of-practice performance testing on all of its hot-mix asphalt (HMA) mixtures. Performance testing is how the Tollway ensures equivalent performance for all mixtures. This combination of material options coupled with final product performance parameters provides long-lasting durable pavements at the lowest costs.

One of the Illinois Tollway projects for asphalt paving contractors includes the Mile Long Bridge project on the I-294 Tri-State Tollway.

In the sandbox

The Illinois Tollway’s process for determining materials options is based on lessons learned through research and field trials using its “sandbox” over the past decade. Because the Illinois Tollway system has primarily full-depth asphalt shoulders, the Tollway is able to use these as a unique test bed for asphalt mixtures without risking mainline disruption. This concept limits risk by using a pavement that has little traffic and can be monitored over time.

The Tollway’s “sandbox” research projects have included:

- Warm-mix asphalt (WMA) technologies

- High-friction aggregates and local aggregates

- Recycled products such as reclaimed asphalt pavement (RAP), fractionated RAP (FRAP), and recycled asphalt shingles (RAS)

- Stone matrix asphalt (SMA) mix designs

- Asphalt binder modifiers including ground tire rubber (GTR) and rejuvenators

Leading this effort is Deputy Chief of Program Implementation Cindy Williams. Williams was previously the quality assurance manager for the Chicago DOT for 20 years, where she introduced performance requirements and facilitated many groundbreaking materials specifications. At the Tollway, Williams drives initiatives to provide performance-based material specifications, and manages the Tollway’s materials engineering team lead by S.T.A.T.E. Testing LLC that monitors and assures the final quality of the asphalt mixtures.

The Tollway has opened its “sandbox” to asphalt paving contractors working on projects such as I-355.

Options aplenty

Throughout the 1990s and early 2000s, the Illinois Tollway made it a point to stay apprised of warm-mix technology research and allowed the first WMA mixes to be placed experimentally on the Illinois Tollway system in 2010, conducting its own research using two warm-mix technologies. In 2012, following evaluation of the trials, the Tollway was the first agency in the country to mandate the use of WMA for all asphalt mix designs.

Today, the Illinois Tollway has a list of approved warm-mix suppliers with specific types and methods determined by existing weather conditions and the amount of recycled materials used in the WMA mixture. For example, when a mixture incorporating high amounts of recycled materials is required to be placed in extremely cold weather, then chemical warm-mix additives must be used. For lower amounts of recycled content or warmer ambient temperature conditions, foaming technology is allowed. Based on these two methods, the Tollway is redefining its 2019 specification to require an increased dosage of a chemical warm-mix when the ambient air temperatures drop below certain temperatures.

In order to maximize the use of locally available aggregates, the Tollway investigated and developed a new specification for aggregate quality testing based on Micro-Deval testing (ASTM D6928). Typically aggregate quality tests include the LA abrasion test to identify aggregate that is not sturdy enough to hold up under higher loadings. Micro-Deval tumbles and degrades the sample while submerged in water. It provides a measure of polish resistance and has proven to be more repeatable than the LA abrasion test. This specification has opened the door for use of local aggregate sources to be used in various mix designs.

The Tollway has been using SMA mix designs for all mainline overlays since 2008. The initial use of SMA was in the reconstruction of the Jane Addams Memorial Tollway (I-90) in the Rockford area as part of a full-depth asphalt pavement constructed in 2008 and 2009 and again for the rehabilitation of a western segment of the Reagan Memorial Tollway (I-88) in 2015. The Tollway’s initial evaluation of local aggregates was conducted in conjunction with that work, and in 2018 five local sources were used in the various mix designs implemented in construction.

There are four categories of RAP/FRAP used on the Tollway system. These distinctions are based on the source and quality of the RAP/FRAP, as well as its processing. RAP/FRAP is considered a valuable resource to the Tollway and all stockpiles are required to have production testing frequencies and tolerances to assure the quality of the source.

One of the first options the Tollway gave contractors was to allow higher percentages of RAP if it was fractionated. While FRAP is more expensive to produce because it requires additional processing, it also is a more consistent product. In 2018, 17 out of 18 of the SMA mix designs used on the Tollway employed coarse FRAP, illustrating that contractors are taking advantage of these options.

In addition in 2008, HMA incorporating RAS was placed on shoulders for the purpose of evaluating performance. For this “sandbox” evaluation, the Tollway required additional production testing to ensure quality and consistency and eventually allowed RAS in any/all mixtures. As the use of RAS increased there was concern about the brittleness of the asphalt contributed to the mixture from RAS. The Tollway reviewed research on performance testing and selected the direct compact tension (DCT) test (ASTM D 7313). The DCT test pulls apart an asphalt mix sample at freezing temperatures (-12°C) and evaluates resistance to cracking. Since the Tollway long ago implemented the Hamburg wheel (AASHTO T 324) performance test to ensure rutting resistance, the implementation of the DCT performance test to ensure cracking resistance was the balance needed to move forward with implementation. “Balanced” is the new buzz word in mix design, and once again, the Illinois Tollway was ahead of the curve in implementing balanced mix designs.

In 2006, the Tollway tried the use of a terminal blend GTR liquid asphalt product. This mix was monitored over time and outperformed many other asphalt mixtures on the Tollway system. In 2015, the Tollway expanded use to include a dry-process GTR and a hybrid GTR (polymer and GTR blend) product on the shoulders. In 2018, the Tollway rolled out its most innovative specification, allowing a number of contractor options based on asphalt binder replacement (ABR), which is the measurement of how much asphalt is coming from recycled products, such as RAS, RAP, and FRAP.

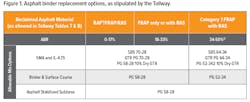

Figure 1 shows the options available, based on type of mixture, as ABR percentages increase. All of these options have Hamburg and DCT performance standards to ensure quality and longevity.

Rejuvenators are the next item to be evaluated in the Illinois Tollway “sandbox.” The Tollway will be allowing the use of rejuvenators on the shoulders as long as they meet current performance standards for Hamburg and DCT, as well as a recovered asphalt binder requirement. Asphalt binders can be extracted and recovered from the mixture designs and evaluated for asphalt binder properties. This provides critical information about the actual performance grade (PG) of the asphalt mix design, which becomes even more important with the increased use of recycled materials.

Keeping it up—on bridges, too

Contractors have a wide range of cost-saving tools to choose from, including aggregates, recycled components, WMA, GTR modifiers, and now rejuvenators. By allowing these options and by specifying performance metrics, asphalt producers are able to customize asphalt mixtures suited for their operations which reduce costs and enhance performance.

For the 2018 construction season, the Tollway contracted nearly 1 million tons of WMA mixtures that included more than 300,000 tons of SMA mixtures. The Tollway saw seven different producers using ABR levels that ranged from 15% to 50% replacement. The choices produced cost savings for the Tollway with bids well below the engineers’ estimate.

In addition to the options allowed for more traditional applications of asphalt mixtures, the Illinois Tollway took an innovative approach to rehabilitate a critical bridge in the middle of a high-traffic area carrying more than 160,000 vehicles a day on the Central Tri-State Tollway (I-294). The existing deck was in poor shape with significant quantities of partial and full-depth patches and is scheduled for a full reconstruct over the next five years. Every day, the deck continued to deteriorate, with potholes and loose concrete causing safety and traffic disruption. A complete deck reconstruction was needed, but with the condition of the deck and imminent winter season, a new approach was needed. An innovative approach was adopted to hold the deck together until it is fully reconstructed. The approach consisted of a heavy application of highly polymerized asphalt tack, followed by SMA. The construction was a success and the Tollway is confident the approach will provide the design service life needed.