Challenging access

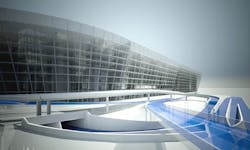

With a total investment cost of around 1 billion Swiss francs, a high-quality superstructure for services is emerging that will provide a usable area of 180,000 square meters at the foot of the Butzenbüel hill and within walking distance of the Zurich Airport terminal. As soon as January 2015, the preparatory and civil engineering work was started for the implementation of the major project. Four buildings, including the P5 and P40 parking garages, were demolished by the spring. At the same time, construction of the necessary structures for accessing “The Circle” were started.

The main drainage pipe from the town of Kloten, which ran though the new development site for historical reasons, also had to be moved. The new building, with its crescent-shaped floor area measuring 37,000 sq meters, is accessed via the Flughafenstrasse and the Butzenbüelring. A ramp bridge from the parking garage (P1, P2, P3) access bridge, which eventually leads into the underground parking garage via the Butzenbüelring underpass, serves as the entrance to the underground garage with 520 spaces.

The exit from the parking garage is via a separate ramp and leads into the Flughafenstrasse. These entrances and exits are entirely free of intersections, and therefore help to improve traffic safety and ensure that regional bus services operate smoothly. An underpass with its own ramp is under construction in the northern part of “The Circle” between the exit ramp from parking garage P6 and the Flughafenstrasse as an exit from the delivery center. The delivery entrance is in the southern part of the building complex and is also used to access the planned Hyatt Regency Hotel.

A multitude of new access structures

In lot 2, the firm dsp Ingenieure & Planer AG, in the engineering team with B+S AG, is responsible for the civil engineering works for “The Circle.” With the exception of the central ramp bridge, which is expected to be built in 2018, the construction work on these access structures is either in progress or already completed.

“The major challenge is building these structures during normal operation, which is only possible in stages and by performing individual activities overnight,” said Oliver Müller, sub-project manager of civil engineering works for the all the access facilities and the responsible divisional head of bridge construction at dsp Ingenieure & Planer. “Planning the excavation pit for the central ramp, which is right next to the Glattalbahn route, was technically demanding.”

Centering for the construction of the central ramp bridge was a major challenge during spatial positioning. According to the current state of planning, this ramp bridge is located in close proximity to a planned protection platform over the Butzenbüelring, which will be necessary to construct the building’s partly overhanging facade. The central ramp bridge also crosses over one point of the current exit from the airport drop-off area at a very oblique angle.

Structures modeled in 3D

Hüseyin Sancak is the senior design engineer responsible for editing the access structures for “The Circle.” The smooth import of 3D data for the existing structures and the planned building complex meant that he had an ideal starting point to integrate the new access structures into these layouts. Although both this data and the digital terrain model were partially developed using software from other providers, the data were exchanged without any problems. Development in the 3D model was particularly useful to ensure that the central ramp bridge was ideally placed, and thanks to the system’s visualization feature, various components could also be optimized in terms of their esthetic design. And these are not the only advantages of editing in the 3D model.

“I can quickly and easily check that the layout is complete during both formwork and reinforcement processes and, in particular, solve geometrically complex details efficiently,” Sanca said. “This function opened new opportunities up to us and showed us how to develop a layout in an extremely efficient manner.”