Ground glass pozzolans and the future of concrete infrastructure

In the spring of 2020 New York changed forever, and not just because of COVID. On March 14, 2020, the last coal power plant in New York State closed in Niagara County, marking a permanent shift away from fossil fuel power and towards more sustainable options.

New York is not the first state to move away from coal, and it will not be the last.

This quiet event is having ripple effects in unexpected ways, such as putting a nail in the coffin of the states’ concrete infrastructure supply chain. Coal power plants not only produce electrical power but also fly ash, a by-product of coal combustion that is used in concrete every day.

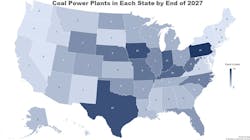

The concrete industry first adopted fly ash in the 1920s as a way to lower costs and improve the strength and longevity of the concrete. It has since been incorporated into most states’ DOT standards. It is a required part of concrete mix designs due to its ability to enhance the strength and durability of critical structures such as bridges. Now, due to extensive plant closures, this required material is becoming impossible to source. By the end of 2027, most of the northeastern and western states will have essentially no locally produced fly ash for their concrete infrastructure.

Slag is a by-product of steel foundries that also has been used in concrete for decades. Fly ash (in some circumstances) can be traded out for slag, offering a potential solution for some infrastructure projects. However, steel foundries in the U.S. have been closing since the rise of Chinese steel manufacturing in the 1980s. In 2021 the United States Geological Survey (USGS) reported: “during 2020, domestic GGBFS [slag] remained in limited supply because granulation cooling was available at only two active U.S. blast furnaces.” This means there are only two places in the country that produce slag; the rest of the U.S. supply is supplemented by countries that have ample steel production.

The shortages have not happened overnight; it has been a gradual decrease for decades. Fly ash and slag were abundant when introduced in the early 1900s, but became harder to find as steel manufacturing went overseas in the 1980s. There is now a severe shortage in several regions. Today the New York State Department of Transportation (NYSDOT) has only one active slag source and zero fly ash sources inside state borders. The state is importing nearly all SCMs for infrastructure projects from outside of the state at a high cost.

The supply problem is not isolated to New York. In 2017 the National Precast Concrete Association (NPCA) reported that “fly ash availability has been significantly reduced.” Members reported that “For the most part, the situation has been, ‘Get in line and wait your turn’”.

Supply is only expected to shrink as time goes on, with 52 more coal power plants across the country are slated to close by 2028. When this happens, the shortages will quickly cascade from isolated regional issues to a full-nation infrastructure problem, with prices rising in turn. National interest in clean power, such as the Biden Administration’s goal of a “carbon pollution-free power sector by 2035” means that this will end with supply dropping to nothing.

The obvious solution is to move the United States’ infrastructure supply chain off this sinking ship and onto new supplementary cementitious materials (SCMs) for our concrete. That is easier said than done.

To have a real impact on the country, the new material must chemically act as an SCM like fly ash does, be readily accessible, available in millions of tons a year, and it must be able to be sourced at a low cost to concrete manufacturers.

With few possible candidates that meet these demands, one solution is rising to the surface—ground glass pozzolans (GGP). Made of glass sourced from beer bottles and salsa jars, this SCM can be sourced at a low price because it is a “waste” material. It also has the advantage of the high, consistent amounts of silica found in engineered glasses. Understanding the significance of glass as a possible tool for the concrete industry, university labs such as Clarkson University’s Center for Advanced Materials Processing (CAMP) have been running tests on glass SCMs for years. This testing has provided a valuable understanding of glass SCM’s performance in concrete.

But the new material is not without its challenges. Glass recycling has been dysfunctional for decades. Recycling facilities have been sending their glass to the landfill almost since the beginning of recycling programs. Manufacturers of GGP can use this glass to make their product, but first, they need to remove the literal tons of other materials like shredded paper and plastic bottle caps mixed in the glass during the recycling collection process.

Removing highly variable contaminates from the glass at a rate of tons per hour is difficult. Until recently it was essentially impossible. This is why glass pozzolans have not been a real possibility for concrete and infrastructure projects. This is why KLAW Industries developed a novel process using a combination of new technologies to remove the contamination with a focus on keeping the cost low.

Using their technology, KLAW Industries can take any glass from the recycling system, remove the unwanted materials, and make an ultra-pure GGP called Pantheon.

The company aims to use Pantheon to solve the looming threat of SCM shortage in its home state of New York and later the whole country, lowering the cost and increasing the supply of SCMs for the nation. KLAW Industries has the ability to do this because the process does not depend on the input material or its contamination rate, consistently producing high purity GGP. This fact will allow the company to source glass anywhere, a requirement if GGPs are going to fill the monstrous shoes of fly ash and slag.

Glass pozzolans not only replace fly ash and slag, they will significantly improve concrete infrastructure. This is because glass bottle manufacturers have already gone through the trouble of purifying and ensuring the quality of the glass and its chemical composition. GGPs take advantage of this, allowing for a consistently high silica purity, a huge change from the inconsistency of fly ash.

Silica is the active ingredient in the beneficial reaction of SCMs. More silica means more strength, more chemical resistance, and overall more durability. Test results of GGPs back this up. When compared to slag and fly ash in concrete core compression tests (AASHTO-T22), glass consistently beats the old SCMs. These results are not the same for all glass pozzolans, but KLAW Industries has shown they can beat slag in strength by 11% at a 20% cement replacement rate (in a 4,000 psi mix). As a bonus to the concrete manufacturers, glass SCMs do this without changing the batching process at all.

Ground glass pozzolans are potentially the future of concrete infrastructure. With more projects incorporating them as a solution to SCM shortages every year, it may only be a matter of time before glass SCMs reach the acceptance needed to be used in large public infrastructure projects. When this day comes, maybe the troubles the industry is experiencing now will be worth it for the new, better SCM that saves money and helps save the planet.