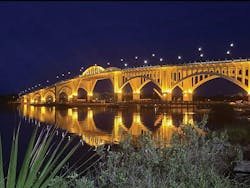

NO. 3 BRIDGE: Veterans Memorial Bridge

The Veterans Memorial Bridge is a new two-lane bridge crossing the Halifax River.

The 1,884-ft-long bridge replaces the existing Orange Avenue bascule bridge with a landmark monumental high-level arch bridge at an elevation of 65 ft. The project included the construction of a new two-lane bridge consisting of open-spandrel arch approaches and a thru-arch main span bridge with 8-ft-wide pedestrian sidewalks with memorial overlooks, a redesigned intersection at Orange Avenue and City Island Parkway, a decorative segmental block wall embankment on the west approach, decorative street lighting, and decorative lighting for the substructure and arches.

The required 65-ft vertical clearance combined with the relatively short bridge length resulted in excessively steep (7%) approach grades. Limited project right-of-way required an “in-line” replacement and a full detour for all traffic.

Through close collaboration with Volusia County, Florida DOT, and the community-led Project Advisory Committee (PAC), a unique and historic replacement bridge design was developed, consisting of open spandrel approaches and a thru-arch main span. The thru-arch main span allowed WSP to reduce the bridge profile, addressing a primary PAC concern. However, this bridge concept presented several design challenges.

First, arch bridges of this type typically utilize cast-in-place (CIP) construction, which results in lengthy construction schedules. Due to the required in-line replacement and full detour, the design team approached this structure type in an innovative way. WSP developed a concept that maximized the use of precast components, including all arch components, so that much of the bridge would be built off-site. This precast initiative resulted in over 50% of the bridge’s concrete work being precast.

The preferred arch bridge concept would typically require a much larger budget than what was available. WSP was able to refine the design by developing a prescriptive construction sequence that significantly reduced the required foundation materials. The precast design approach also resulted in a unique structure that contractors might view as risky. To mitigate contractor risk, the design team developed a full 3-D design and bridge visualization sheets that clearly showed how the precast elements had to be assembled.

During the design phase, cost savings were realized by relying on a restrictive construction sequence in order to reduce the size of the substructures. There were also restrictions placed on pile installation during construction due to concerns with lateral forces from the arches causing installation delays. The general contractor tasked their erection specialty engineer with re-sequencing the construction sequence to allow for flexibility and concurrence, resulting in significant schedule recovery.

The Veterans Memorial Bridge project was one of the first projects for Finley to apply its BrIM technology where both the analysis model and 3-D production model are produced from one another. With the large number of concrete elements and multiple variations of temporary work structures, one of the challenges for the engineering was to interface all of the design elements to produce a seamless workflow for construction. With the 3-D BrIM workflow, Finley was able to alleviate this complex challenge.

“The mixture of the precast construction method and the complex erection sequence with multiple variations of temporary works attracted Finley to this traditional concrete spandrel arch bridge,” Ivan Liu, P.E., Finley Engineering Group Bridge Engineer, told Roads & Bridges. “The Veterans Memorial Bridge gave Finley the opportunity to showcase its BrIM workflow that helped efficiently produce the construction analysis model and fabrication drawings for the project.”

Due to the short approach area, the bridge was designed with an aggressive 6.5% grade for both approaches, resulting in some construction difficulty and concrete mix considerations. The superstructure units consist of concrete decks supported by 72-in.-deep prestressed concrete Florida I-beams that was the county’s first use of the new standard Florida precast concrete beams. In addition, the prestressed concrete beams were designed with higher strengths at 8,500 psi in order to maximize the efficiency of the span arrangements.

The 15-span bridge was constructed using Florida I-beam prestressed beams on the traditional approach spans measuring from 80 ft long to 108 ft long. The approach arch spans were constructed using four total arch sections, assembled to create two arches joined with a closure pour. These arches then had spandrel columns cast on them to support transverse t-beams, resulting in a 144-ft span. The 221-ft-wide main span was created using six main span arch sections assembled with falsework and connected with closure pours to create the two signature arches reaching 90 ft in elevation.