Like any community in the Upper Midwest, the city of Edina, Minn.—population 50,000—experiences its fair share of potholes. And like communities across the U.S., Edina has aging road infrastructure in need of repair. In June 2019, the city opted to invest in a piece of technology that could address both of these issues: a Roadpatcher from Schwarze Industries.

According to Chet Boom, an asphalt worker for Edina’s public works department, keeping up with the sheer volume of pothole repair and road maintenance can be a challenge. In his 11 years working for the city, he said, Edina has used a combination of hot-mix asphalt, cold-mix asphalt, and spray patching methods for pothole repair. The city opted for the Roadpatcher in large part because it improves efficiency by allowing for a single operator to conduct spray patching repairs, he said.

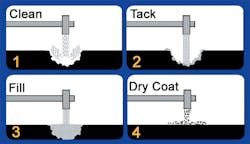

Repairs with the Roadpatcher utilize a four-step process. First, loose rock and debris are cleaned from the pothole. “Then, we will spray a layer of tack oil that acts as a binder to the sides of the hole for the new filler material to stick to,” Boom said. Next, a hot asphalt emulsion and aggregate mixture fills the hole. “Once the pothole is filled with the mix, we then cover it with a layer of dry rock to prevent bleed-through and vehicles tracking oil all over,” Boom concluded. The operator is able to conduct the entire process from the comfort and safety of the cab—another major factor in Edina’s decision to purchase the Roadpatcher.

Edina typically conducts spring and fall “pothole sweeps” during which the city has “crews working in neighborhoods catching up on anything that has opened up, though we do try to keep up throughout the course of the year,” Boom said.

The city also has mill and overlay and neighborhood reconstruction programs to help reduce the need for pothole repair. According to Boom, along with using it for pothole repair, Edina has been able to utilize the Roadpatcher to blend the edges of concrete road panels, seal seams between paver passes in the center of the road, and level areas of roads that have settled.

In addition to efficiency and operator safety, customer service was a major factor in Edina’s decision to purchase the Roadpatcher. The city worked with equipment dealer RCM Specialties, which has provided training and support as operators learned to use the Roadpatcher, Boom said. Although much of the operator training occurred on the job—according to Boom, it’s “really the only way to learn how to use the machine”—he was grateful that RCM made itself available for support. “A big help was [that] while I was out in the field, I could always call RCM with questions,” he said. RCM also provided maintenance training to help familiarize public works department employees with the Roadpatcher’s engines and hydraulic systems.

According to Boom, since Edina began using the Roadpatcher, the city has found that the equipment’s all-in-one repair process has improved efficiency by allowing operators to move quickly from one site to another. Another benefit has been the quality of the repairs, with the Roadpatcher utilizing “a patch material that has good adhesion for repairs around utilities such as gate valves and manholes [and] good adhesion on our concrete streets.”

So far, Boom said, the people of Edina have been pleased with the results of using the Roadpatcher as well. “I think generally the public's response has been positive,” he said. “They are always glad to see potholes being filled.”