By: Neal Hawkins, Omar Smadi and Skylar Knickerbocker

Determining the appropriate application of pavement markings is a persistent challenge for departments of transportation.

A team of researchers from the Iowa State University Institute for Transportation recently partnered with the Minnesota Department of Transportation (MnDOT) to conduct a field trial to evaluate the marking performance of different combinations of pavement marking materials and installation practices on challenging surfaces. The trial included a range of pavement marking products over varied roadway characteristics, classified by product, thickness, bead package and whether or not a primer was applied.

MnDOT has experienced poor pavement marking performance on “non-smooth” roadway surfaces such as sealcoat and microsurface-treated roadways, sometimes referred to as “challenging surface” roadways. Consequently, the trial project was implemented with the goal of generating information to support MnDOT operational practices across all districts and aid in the development of technical memorandum guidance.

The research team worked with the technical advisory panel (TAP) to document pavement marking performance on several municipal roadways within the city of Eden Prairie, Minn. These projects provide pavement marking performance on challenging surfaces information over different conditions (traffic levels and line types) apart from the MnDOT research test deck scenarios. Seven different locations were measured, all of which were on sealcoated roadways that were installed in either 2012 or 2013.

When considering roadways for resurfacing, MnDOT typically selects a sealcoat surface for lower volume roadways with minimum rutting. In contrast, microsurfacing is selected for higher volume roads and/or roadways with moderate rutting. In general, most of the sealcoat projects are for two-lane roadways with microsurfacing typically applied to the four-lane roadway sections.

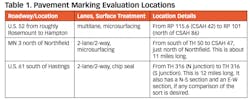

Based on these conditions, the research team worked with district staff to identify sealcoat and microsurface project locations (for the 2013 construction season) that would support the pavement marking evaluation. Given a desire by the TAP that the pavement marking evaluation be a part of a paving project, the final roadway selections were made at three 2013 paving projects within the Metro district, the details of which are shown in Table 1. A small segment, roughly 3 miles in length, along each roadway would be used for the pavement marking evaluations. The research team worked with the project TAP to develop a draft evaluation plan, which would be applied to each roadway. This draft plan identified the test sections by number, subsection, length, whether or not a primer would be applied, the test marking material, material thickness and line types to be evaluated.

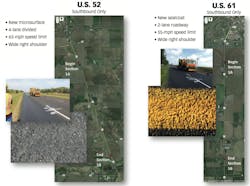

A side-by-side comparison of the two test sections.

The process begins

Researchers worked with the city of Eden Prairie to gain some knowledge of its existing challenging surface practices. The city identified several sites that had new challenging surfaces (sealcoat or microsurface) installed within the last several years. Each site was visited by the team and documented. The city noted that, starting in 2013, it changed its practice, by which these type of roads were initially striped with latex paint and then restriped a year later with epoxy. At each location, a series of 16 retroreflectivity measurements were taken per direction of travel over a roughly 400-ft section. All measurements were made using a hand-held LTL-X device. The retroreflectivity values were placed in a scale from 0 to 500 millicandelas per sq meter per lux (mcd).

From these results, researchers were able to gauge the effectiveness level of Eden Prairie’s present practices as a control against their own test decks.

In August 2013, test decks were installed on U.S. 61 and U.S. 52, based on the team’s final evaluation plan. The test sections had newly placed surfaces: sealcoat on U.S. 61, and microsurface on U.S. 52. The primer chosen was standard latex paint at a 15-mil wet thickness. The truck was calibrated to 4 mph for 35 wet mils application and 5.5 mph for 25 wet mils.

The marking materials chosen were as follows:

- Latex was standard MnDOT latex material (12-mm wet thickness) for control, and also was used as primer. Coloration: White was UC1515 and yellow was UC3590. A MnDOT Metro district latex truck was used to paint primer sections on both roadways and for all applicable sections. The primer installation included M-247 glass beads per MnDOT direction (installed 24 hours prior to permanent striping);

- High-build waterborne: Fastrack HD21A at 25-mm wet thickness. Coloration: White was VLX15562 and yellow was VLX15563. Reflective media included Visiblend;

- High-build waterborne: Fastrack HD21A at 35-mm wet thickness. This included the Visilok drying agent, and reflective media included Visiblend;

- HPS-4, standard MnDOT epoxy material at 12-mm wet thickness. Reflective media included standard MnDOT M-247; and

- MFUA-10, standard MnDOT-modified urethane material at 12-mm wet thickness. Reflective media included standard MnDOT M-247.

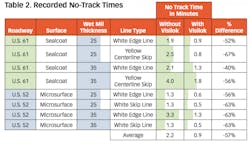

The M-247 glass beads were applied at 8 lb per gal. The Visilok drying agent was applied at 2 lb per gal on both the 25- and 35-mm paint applications. Visiblend was applied at 10 lb per gal and consisted of Type 1 and 3 beads with 15% Ultra 1.9 beads blended. The Visilock drying agent speeds up no-track dry times and allows agencies to use thicker, and presumably more durable, marking materials. Recorded no-track times are shown in Table 2.

Measuring and monitoring

Retroreflectivity readings were measured using a hand-held retroreflectometer (LTL-X). The standard test procedure defined by ASTM 1710-11 was followed in determining the coefficient of retroreflected luminance of horizontal coating materials used in the test pavement markings.

Based on MnDOT skip-line spacing, 16 measurements were taken over 400 ft within each test segment. The process included the following:

- Calibrate the handheld instrument according to manufacturer recommendations;

- Pre-load section labels by roadway in the LTL-X;

- Locate each field sampling section using roadway markings in-place; select areas typical of the marking section;

- Take all measurements in the direction of travel;

- Center the device on the pavement marking and for each edgeline, take 16 equally spaced readings within the 400-ft sampling area regardless of the condition of the line. On each lane line, take two readings on each skip for 8 consecutive skips; and

- Data entry for handheld instrument: Select the test section from the pre-loaded list and take retroreflective readings using the defined procedure.

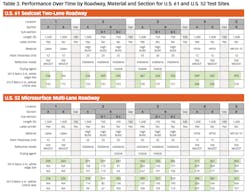

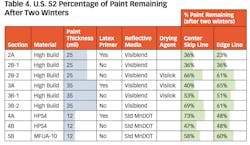

Initial readings were taken in fall 2013. The U.S. 61 test deck failed as a result of pavement material issues and was dropped after initial measurements. However, U.S. 52 was measured subsequently in winter 2014 and winter 2015. Two sections on U.S. 52 (the latex on sections 1A and 1B) did require restriping prior to the 2014 field measurements. This resulted in the elimination of these sections of the U.S. 52 test deck from the study. Performance of the applied markings over time by roadway, material type and test section, as well as average retroreflectivity measurements, for all three reading periods are shown in Table 3. The average percentage of paint remaining on U.S. 52 after two winters is shown in Table 4.

Conclusions drawn

The U.S. 52 evaluation provides the basis for the following conclusions:

- Latex (12-mm thickness): The two latex sections installed (with and without primer) did not perform and had to be repainted in 2014, after less than one year of performance;

- High-build paint: For the 25 mm thickness, the latex primer improved the performance of the pavement marking material. The average for white skip/edgelines was 98 mcd with a primer compared to 83 mcd without. When the material thickness was increased to 35 mm, the primer was not found to have an impact;

- Epoxy: The two epoxy materials used, HPS4 and MFUA-10 (both at 12-mm thickness), provided good performance after two winters, regardless of whether a primer was used or not; and

- Material thickness: Without the sealcoat test results for U.S. 61, it is not possible to contrast the impact of marking material thicknesses based solely on the microsurface on U.S. 52. There is evidence, however, that an increased material thickness improves performance given the results of the 12-mm latex and 25-mm high build. When the material thickness increases above 25 mm, there appears to be enough material to cover the surface voids (resulting from a challenging surface) and still have good performance without a primer.

About The Author: Hawkins, Smadi and Knickerbocker are with the Institute for Transportation at Iowa State University.