By: Colin Brooks, Richard Dobson and David Banach

Back in the September 2015 issue, Roads & Bridges examined the use of unmanned aerial vehicles (UAVs, unmanned aerial systems [UAS] or “drones”) in various DOTs across the U.S.

One agency of interest was the Michigan DOT (MDOT). MDOT began to use UAS for bridge inspections, confined space inspections and traffic monitoring. Steve Cook, P.E., engineer of operations and maintenance at MDOT, had been working with Colin Brooks of the Michigan Tech Research Institute (MTRI) to determine how these tools could most effectively be used. With the rapid advancements in UAS rules, technology and sensors, MDOT and MTRI have continued to investigate even further how these platforms and sensors can be implemented into department procedures.

Due to the widespread interest in using UAS for both commercial and recreational purposes, the Federal Aviation Administration (FAA) has been updating regulations. At the time of the aforementioned September 2015 article, the FAA required all commercial UAS operators to obtain a Section 333 exemption and/or a certificate of authorization (COA). Since then, the FAA has adopted the Part 107 Remote Pilot License certification. Now, any individual who wishes to pilot a UAS is required to take the Remote Pilot Knowledge Test to gain a Remote Pilot License, permitting flights in certain airspaces. The September 2015 coverage also mentioned concern of public perception of UAS, but since then many agencies and businesses have incorporated UAS into their programs. Additionally, to assist in minimizing traffic disruptions due to roadside drone use, some DOTs have even started using notification signs indicating such operations.

The Michigan DOT has been using UAS for bridge inspections, confined space inspections and traffic monitoring. Due to the widespread interest in using UAS for both commercial and recreational purposes, the FAA has been updating regulations.

Planning the next flight

With the success of the initial UAS project, MDOT was interested in further investigating how UAS could be implemented within the agency. A request for proposal for a two-year Phase Two research project on how UAS could be implemented into infrastructure assessments was released, with MTRI’s bid being selected again. By the end of the second phase, five bridges, three road corridors, and one construction site all had been imaged using UAS with optical and thermal technologies. Additionally, various-sized platforms, such as smaller-sized DJI Mavic Pro and DJI Phantom 3 Advanced, and larger-sized Bergen Hexacopters and a Bergen Quad-8 UAS, were used to make multiple flights over the transportation assets. The smaller-sized platforms typically flew for a maximum of 20 minutes and provided quick overviews—notably in hard-to-access areas. The larger-sized platforms typically flew for 15 minutes, but were able to carry heavier payloads up to 10 lb.

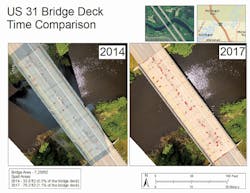

As with the first phase, UAS-based bridge deck assessments proved successful, as both optical and thermal imagery were able to detect spalls and delaminations, respectively. For spall detection, the high-resolution optical imagery was processed into a 3-D digital elevation model. A custom-made spall detection algorithm was created for MDOT that used the 3-D model and user input to automatically detect and quantify spalls on the bridge deck. Likewise, for delamination detection a custom-made algorithm was created, using the merged thermal imagery of the bridge deck to detect and quantify delaminations. A comparison between traditional manual (hammer sounding and chain dragging) and automatic UAS delamination detection also was conducted. Traditional manual methods detected delaminations at a coarser scale, whereas UAS were able to detect the distresses at a finer scale, often outlining the exact boundaries of the features.

During Phase One, a traffic monitoring blimp was flown along a highway corridor to live-stream video imagery of traffic. However, further testing indicated that the blimp was not properly suited for high wind events. Therefore, for Phase Two the DJI Mavic Pro with onboard optical camera was used to monitor traffic. Using the UAS proved more useful than the blimp due to its stability and ability to be flown along the corridor as compared to a stationary blimp. Michigan Tech developed a custom program for MDOT that automatically quantified the traffic count, traffic flow and speed of the vehicles.

Michigan Tech also used UAS to image an active construction site, collecting optical imagery of an aggregate pile. A different company also imaged the site using a high-resolution light detection and ranging (LiDAR) system. The optical imagery of the pile was reconstructed as a 3-D model in which volumetric measurements were made and compared to the LiDAR measurements. Results showed that the optical imagery quantification was comparable to the LiDAR measurements. This shows that high-resolution optical imagery could potentially be used by MDOT in the future to measure the change in volume at active construction sites.

The Michigan Tech team recommended that MDOT use data captured by UAS to ingest into element-level data models of bridge surface damage elements. The purpose of these cost-benefit models was to attach data structures that reflect the age of the bridge surface, the point in time the element is captured and its progression through the bridge life cycle. This process can help optimize the cost of bridge maintenance and rehabilitation.

Storing and viewing data

Several different types of data transfer sites were investigated and tested during the course of the project to find a solution to quickly upload, provide access for, and distribute the UAS-collected data to multiple MDOT users. A final cloud-storage software setup was selected to allow Michigan Tech and MDOT to collaborate and transfer files easily. The system also allowed MDOT to directly upload the data from the cloud into its own databases. The advantages of this solution included a unique credential (ID/password) for each user, a full audit trail and a data backup mechanism stored within the secure cloud. System managers also could quickly identify any changes to the files or the cloud performed by the users.

To ensure that the cost of using UAS to assess bridge deck conditions did not outweigh the benefits, a cost-benefit model was developed to compare the overall economies of the two comparable traditional manual techniques to UAS. While the traditional methods are simple to use, economical, and hence a widely adopted NDT technique for inspection of bridge decks, distress data from these methods can be subjective and variable. The Michigan Tech team recommended that MDOT use data captured by UAS to ingest into element-level data models of bridge surface damage elements. The purpose of these cost-benefit models was to attach data structures that reflect the age of the bridge surface, the point in time the element is captured, and its progression through the bridge life cycle. This can be very useful in further improving bridge deterioration models as a function of how individual distresses behave over time, providing a baseline for assessing the quality of data captured in NDT techniques, and improving the accuracy and precision of the assessed bridge condition. In turn, this can help optimize the cost of bridge maintenance and rehabilitation.

UAS-based bridge deck assessments proved successful as both optical and thermal imagery were able to detect spalls and delaminations, respectively.

Future flights

This applied research project enabled the continued testing and demonstration of multiple UAS platforms and sensors for infrastructure needs. UAS-based sensing has become more practical with the release of the updated FAA regulations. The resulting data products showed the ability to rapidly and accurately detect bridge deck surface and subsurface condition issues using UAV-collected imagery, how a construction site could be quickly imaged to include aggregate quantities, and how small UAVs can be used to evaluate traffic conditions. Improvements to the collection, processing and visualization of data originally developed under the first phase of this project were enabled throughout the secondary phase, including improved spall detection and delamination detection software tools.

UAS have the potential to collect critical data inexpensively and accurately. As compared to the first phase of this project, the number, types, and resolutions of platforms and sensors available for practical deployment have changed dramatically, as well has the number of people using UAS for research and operational purposes. Future flights are needed to make these applications and workflows part of day-to-day usage for MDOT, especially under developing federal rules that are increasing the practical deployment of UAS.

About The Author: Brooks and Dobson are with Michigan Technological University. Banach is with the Michigan Tech Research Institute.