By: Chris Pourteau

From the semi-arid northern plains to the humid subtropical piney woods, Texas’ sprawling network of roads—nearly 700,000 lane-miles of them—span multiple climates.

The temperature and landscape variances over such a vast area can wreak havoc on roadway maintenance. Many shortcomings arise when historical specifications are used with maintenance binders, such as:

- Lack of a tie to the climate;

- Measurement of empirical properties not tied to performance;

- Lack of consideration of appropriate aging and low temperature conditions; and

- The inability to test binders modified with polymers of recycled tire rubber.

Chip seals—which are the preferred, cost-effective maintenance treatment of choice for many state departments of transportation (DOTs) today—are composed of a spray application of asphalt emulsion or hot-applied asphalt cement covered with aggregate. They waterproof the road and provide a new friction surface. However, to test the binders used in chip seals, most practitioners still use specifications established in the early and mid-20th century.

“Although testing and specifications have evolved since the early days of asphalt application, those early tests didn’t directly account for environmental factors,” explained TTI Research Engineer Amy Epps Martin. “And much of that inflexibility remains in the current methods accepted as national standards for testing chip-seal binders.”

Different traffic levels on a roadway, as well as different temperatures in the surrounding environment, can have a huge impact on chip-seal performance. And when the binder fails prematurely prior to its expected six- to eight-year service life, additional maintenance is needed to waterproof and promote safety. And that can add up quickly for state DOTs already cash-strapped by reduced revenues and increased responsibilities for maintaining their local transportation systems.

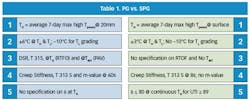

It took some time

Over the past two decades, there’s been an effort to modernize chip-seal binder specifications using the performance-grade (PG) binder specification for asphalt concrete as a model. This PG specification was developed in conjunction with the national Strategic Highway Research Program (SHRP) from 1987 to 1992 with subsequent implementation. The PG specification addresses the shortcomings of historical specifications and requires constant material properties while allowing temperature to vary in order to meet established thresholds for performance. That was a significant shift from the old “test at a constant temperature approach.”

PG specifications require asphalt concrete binders to meet certain thresholds over the entire range of temperatures a roadway might experience. This provides longer-lasting, more-reliable performance and reduces the frequency of maintenance and the associated costs for DOTs. For example, the PG 64-22 grade indicates an asphalt concrete binder will resist rutting at 64°C and low-temperature cracking at -22°C, and is, thus, ideal for roadways that experience that range in temperatures. Thus PG binder grades reflect where (and under what environmental conditions) they should be used.

Binder is spray-applied in a single, smooth pass in advance of aggregate placement.

Texas began implementing the PG specifications for asphalt concrete binders in 1997, and Darren Hazlett, then a supervising chemical engineer with the Texas Department of Transportation (TxDOT), asked a simple question—if we’re changing how we characterize asphalt concrete binders, why not do the same for chip-seal binders? Over the past two decades, TxDOT has sponsored multiple research projects with the goal of developing and validating a surface performance-grade (SPG) specification for use in selecting and grading chip-seal binders.

“I’ve been working with Darren on developing this specification almost my whole professional career,” explained Epps Martin. “It’s become almost a calling for both of us.”

TxDOT research projects 0-1710 and 0-6616 developed and validated the SPG specification using laboratory measurements and thresholds and comparing expected performance to field performance monitored through visual distress surveys that evaluated aggregate loss and bleeding in 75 roadway sections. The two principal concerns were to 1) account for differences in climate, and 2) employ performance-based properties that could be measured with existing equipment used with the PG specification. Making the new specification easy to implement (without requiring new capital investment by the DOT) was a key concern.

The original SPG specification established in 2001 related the properties of chip-seal binders in service to the expected environmental conditions with respect to pavement temperatures and appropriate aging to preclude the dominant distresses of aggregate loss and bleeding. In 2012, the SPG system was refined in TxDOT research project 0-6616. The key to a chip-seal binder performing as expected for its service life is to ensure it lasts past the first year. After that, failures that require significant maintenance fall off dramatically, and the chip seal usually makes it to the end of its expected service life.

When comparing the expected performance of the binders (based on their SPG grade prior to adoption of the specification) against actual field performance after one year, 30 roadway sections built in 2011 returned an 80% overall correlation. Nineteen sections built in 2013 returned an 89% correlation at high temperature (TH) for bleeding and 68% correlation after two years at low temperature (TL) for aggregate loss. And 24 sections built in 2014 resulted in a 71% correlation at TH and 75% correlation at TL. Sometimes binders can fail in the real world due to increased use of the roadway by traffic or poor construction practices that result in insufficient embedment of the aggregate in the chip-seal binder. These factors were accounted for when comparing laboratory performance and field performance. A phase-angle parameter also was introduced in the SPG specification to ensure modified binders contained sufficient polymers.

Though the SPG has been validated through these studies, it has yet to be widely adopted as standard practice by the state.

“The selection of seal-coat binders is still based mainly on experience and traditional specifications that aren’t performance related and don’t directly consider climate,” noted Epps Martin. “Our ultimate goal is to replace TxDOT’s current Seal Coat Binder Tier Selection Table and Item 300 Seal Coat Binder Properties requirements in service.”

A map was developed to show recommended climate-based SPG grades, but usually the useful temperature interval (UTI) will be expanded due to expected high traffic volume and/or the desire to utilize modified binders.

TTI is currently working with TxDOT to implement the SPG specification in the Lone Star State. In 2015, a large chip-seal project in TxDOT’s Corpus Christi District served as an initial test bed for the new specification. After the first year of in-service performance, the research team will evaluate the results and revise the specification as necessary. At least another six of TxDOT’s 25 districts are planning to implement the SPG specification in 2016.

“The SPG specification is ready for implementation, and this effort will provide further validation with additional highway sections, corresponding climates and a wider variety of materials,” said Hazlett, now deputy director of TxDOT’s Construction Division. “It’s been a long time coming, but we’re hopeful this new specification will result in increased performance and reduced costs for TxDOT.”

After nearly 20 years spent developing the new SPG specification, Hazlett and Epps Martin are still leading the charge to implement it statewide. With two rounds of validation completed, and a third currently underway, they’re in the midst of the four-year, staged validation effort that examines field samples in the laboratory as they continue to refine the specification and compare expected performance to actual field performance. “Even small improvements in performance can save lots of money,” noted Epps Martin. “It’s all about getting past that one-year threshold.”

More reliable

The new SPG specification ties chip-seal performance to local climatic and traffic conditions, allowing the agency responsible for maintaining its community’s roadways to select a reliable chip-seal binder in service (either hot-applied or emulsion residue) with improved performance and thus incur less out-of-cycle maintenance requirements and reduced costs as a result.

“Texas spends approximately $300 million per year on a chip-seal preventive maintenance program,” said Hazlett. “Conservatively speaking, if only 1 in 5 of the state’s seal-coated roads could achieve a 15% improved lifespan, Texas could save $9 million per year.”

Hazlett, Epps Martin and their TTI-TxDOT team are continuing the third round of validation of the SPG specification in 2016. R&B

About The Author: Pourteau works in marketing and communications for the Texas Transportation Institute.