By: Mo Ehsani, PhD, P.E., S.E.

In the late 1980s, the author introduced the concept of repair and strengthening of structures using fiber reinforced polymer (FRP) products. The original concept uses a technique referred to as wet layup. Fabrics of carbon or glass typically 12 to 48 in. wide are saturated with an epoxy resin in the field. The fabric is applied to the surface of the beam or wall, or wrapped around a column to increase the flexural, shear and confinement of such elements. Within a few hours, the epoxy cures in ambient temperature and the FRP reaches a tensile strength that is two to three times that of steel. In the following decades, these techniques have gained significant popularity and are being used globally to extend the service life of many bridges. Among the advantages of FRP are light weight and ease of handling, speed of construction, and high chemical and corrosion resistance.

Recently, the author has developed several new FRP systems that offer faster and higher-quality repairs. In some cases, these products provide solutions that could not be addressed with the old wet layup system. This paper focuses on two of these new products which are used to repair piles, columns and culverts.

The first product called PileMedic is a new type of pre-cured glass or carbon FRP laminate that is about two to three times stronger than steel. During the manufacturing process, one or more layers of carbon or glass fabric are saturated with resin and pressed together under heat and pressure to create a solid laminate with a thickness of only 0.02 in. The 4-ft wide laminates are supplied in 300-ft-long rolls. In the field, the laminate is cut to a length slightly more than twice the perimeter of the column being repaired; the second half of the laminate is coated with a layer of epoxy paste. The thin laminates are flexible enough that they can be wrapped around the deteriorated pile or column to create a two-ply shell of desired shape and size; the annular space between the shell and the column is filled with grout or resin. The jacket provides significant confinement, flexural and shear strength for the repaired column.

Independent tests by the U.S. Army Corps of Engineers, Caltrans (for earthquake-damaged concrete columns), Texas DOT (for corroded steel H piles), and Nebraska Department of Roads (for deteriorated timber piles) have verified the unique contributions of this product to rehabilitation of such structures. Among the features of the new system is its adaptability that eliminates long delays to order and manufacture jackets of specific size and shape.

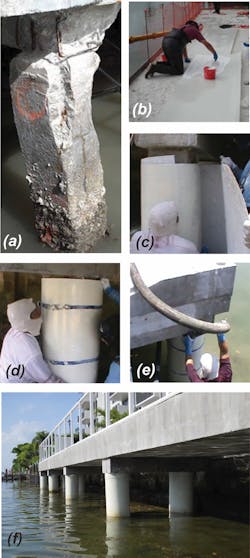

One of the applications of this product is for repair of steel piles. The original wet layup system, for example, cannot be sued to repair such columns because the fabric cannot be bonded to a corroded steel shape. Figure 1 shows the first application of PileMedic to repair 50 bridge pilings in St. Louis, Mo., in 2010. The steps include cleaning and removing the corrosion, cutting the slab around the piling, applying an epoxy paste to the surface of the laminate, and wrapping it around the piling to create a shell. Temporary ratchet straps can be used to maintain the shape of the laminate while the epoxy cures. At this stage, the shell is not bonded to the piling and can be pushed down to rest on the soil below the slab. The annular space between the shell and the steel piling is filled with an expansive grout. If required, reinforcing steel bars also can be inserted in the annular space. The lower right image shows the repair after the ratchet straps have been removed and the exterior surface of the shell has been coated with a textured finished resembling concrete. In addition to restoring the strength of the piling, the impervious shell will protect the steel piling from future attack by moisture and deicing chemicals, ensuring a long-lasting, maintenance-free repair. A video of this installation can be found here.

Figure 2

For columns that are submerged in water (Figure 2), the laminates can be coated with a special epoxy that cures underwater. This eliminates the need for coffer dams and can significantly reduce the cost of such repairs. The 4-ft wide laminate is wrapped around the upper portion of the column to create a 4-ft tall shell. This shell is lowered, and another 4-ft tall shell is similarly constructed and bonded to the first one. The 8-ft tall shell is lowered into water, and this process can continue until the desired height of the column is encased in a shell. At this time the bottom of the shell is sealed, and the annular space is filled with a tremie grout. A video of this project is available at this link.

Figure 3

Many secondary and county roads are served by timber bridges. The piles in these structures decay and rot after a few years of service. In many cases, such as for one particular bridge in Montana, the piles may be attached to the abutment wall (Figure 3). This makes repairs difficult. Using a saw, an opening is cut behind the pile and the epoxy-coated PileMedic sheets can be passed through the small opening to create a strong structural shell around the pile. If desired, the small annular space can be filled with a low-viscosity resin. Such resins penetrate through all the cracks and crevices of the pile, making it significantly stronger than the original undamaged pile.

The second product, called StifPipe, is a new sandwich construction FRP pipe that received the 2016 ASCE Innovation Award as the world’s first green and sustainable pipe. Various layers of glass or carbon FRP are wrapped around a honeycomb core to create a lightweight, rigid and strong pipe that can resist all external loads even if the culvert fully deteriorates. The pipe can be made on site or very close to the site to minimize transportation charges. The pipe segments can be used to slip-line culverts where the strength has been compromised by corrosion.

Figure 4

Many culverts have a non-circular cross section, and slip-lining these with a circular pipe will result in significant loss of flow capacity. The unique manufacturing technique of StifPipe allows the pipe to be made to any shape, including oval, rectangular, etc. (Figure 4). These pipes can be built to a size that would minimize the annular space between the pipe and the host culvert.

Figure 5

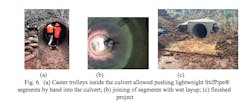

In one of its first major applications presented here, the technology was used to repair an 80-ft long, 60-in.-diam. culvert in a remote site more than a 1,000 miles north of Brisbane, Australia, in July 2015. The culvert had partially collapsed to a diameter of 55 in. The custom-made pipes were manufactured (Figure 5) outside a diameter of 51 in.

Figure 6

The lightweight pipe could be installed with no need for jacking equipment on the remote site, resulting in significant cost savings (Figure 6). The repairs were successfully completed in 4 days with no traffic disruption. A video of this project is available here.

About The Author: Ehsani is president of QuakeWrap Inc. and Centennial Emeritus Professor of Civil Engineering at the University of Arizona.