By: Angus W. Stocking

The Florida Department of Transportation (FDOT) knew that the big box culvert running under State Road 64 in downtown Bradenton, Fla., either had to be replaced or rehabilitated—the question was how.

“We’re not even sure how old this culvert is, but judging by the square, twisted rebar, it appears to have been built sometime in the 1920s,” said Rick Hogue, senior construction team leader for Stantec, a multi-national contracting firm. “And that’s a long service life for any culvert.”

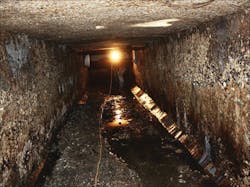

Ninety years later, the culvert, which is about 6 ft by 6.75 ft in cross-section and 61 ft long, was facing catastrophic failure. There were large cracks, holes and a generally compromised matrix. The condition of the culvert was so poor that FDOT’s project specifications required solutions that were “stand-alone;” in other words, the existing culvert was judged to have no structural integrity.

Methods Considered

But finding an adequate repair or replacement method was a major challenge. For structural reasons, replacement seemed like the best choice, but city, county and state officials ruled out shutting down this roadway, which is one of the state’s busiest commuting routes. The culvert itself also presented major obstacles to repair: It shares space with several utilities and is intersected by large storm water outfall lines.

Replacement also would be complicated by the need to maintain connection with the upstream and downstream 60-in. reinforced concrete pipe storm sewers: The culvert is extremely active and handles tidal surge as well as storm activity. Thus, replacement was ruled out.

A version of sliplining was considered, where arched pipe would be inserted into the culvert and the voids would be filled with concrete. In some situations, this would have worked well, but not here. The utility pipes and the storm interceptors added too much complication; cutting and adapting pipe sections would take a lot of time and compromise structural integrity. This solution also would reduce sewer capacity and require large staging areas. Because this project would take place in downtown Bradenton, maintaining a tight project staging area would minimize the need for transportation management.

With two plausible rehabilitation methods discarded, FDOT needed ideas. Fortunately, the general contractor, Gibbs & Register Inc. (G&R), and one of its subcontractors, TV Diversifed Inc. (TVD), had a good one. Their proposed solution would rebuild the culvert from the inside with sprayed, reinforced concrete. This would easily accommodate the utilities and storm interceptors, and would not disrupt traffic or significantly affect flow capacity. There was one problem: The method being used had never been performed in Florida before. Sprayed concrete casting had been used successfully in large-diameter circular pipe through a process known as centrifugally cast concrete pipe (CCCP). CCCP was developed by AP/M Permaform and relies on a spincaster and high-strength grouts and is a reliable “no dig” rehabilitation method. Now for the first time in Florida, a similar technique would be applied to a rectangular culvert.

The Solution

“Initially, it sounded like a great idea—may be too good to be true,” said G&R Project Manager Joel Covitz. “As we worked through the various issues, we realized that the biggest hurdle, really, was obtaining approvals.” Indeed, with city, state and county officials all intensely interested in the project, getting approval for an untested solution seemed like a long shot. “FDOT had guidelines and policies for solutions similar to this, but not for something exactly like this,” Covitz said. “In fact, even G&R’s engineers had reservations. By moving forward patiently and addressing all concerns and questions, we were gradually able to win people over.”

The key factor turned out to be the “stand-alone” requirement. TVD produced engineered plans showing that the sprayed concrete culvert was structurally viable, even without support from the surrounding culvert. With this assurance, approvals were issued, and the project proceeded. Engineered features of the culvert design included 18-in. radius top corners to improve overhead load distribution, and 5-in.-thick walls. This thickness actually exceeded structural requirements, but provided 3 in. of cover over reinforcing metal to prevent corrosion from brackish tidal water.

Fast and Straightforward

For a bypass system, TVD used X2 60-in. pneumatic pipe plugs on each end of the culvert, with flow-through pipe. The contractor knows Florida and therefore created a control option to deflate and inflate the plugs for daily management of storm water flows resulting from tides or sudden rainfall. The existing culvert surface was then pressure washed, and loose, unsound concrete was chipped away. Voids or cracks were filled, and the interior substrate was leveled with MS-10,000/UL, a high-strength cementitious grout.

MS-10,000 UL, used as stabilizing underlayment, and MS-10,000, which was used for all the concrete spraying, are both made by AP/M Permaform. They are ultra high-strength corrosion-resistant mortars based on Portland cement and fortified with micro silica and other densifying agents. Graded quartz sands and fibers are added to improve cohesion and flexural strength. They perform well in moist application conditions and adhere tightly to most surfaces. TVD typically uses MS-10,000 and other AP/M Permaform products on CCCP projects, which gave them confidence that it would perform well when applied by spray to the culvert. Crucially, MS-10,000 also cures quickly and bonds well to itself, so thin layers can be added to pipe and culvert on successive days without cold joints, enabling TVD to achieve the 5-in.-thick design specification.

With the culvert substrate cleaned and stabilized, the TVD team then built a metal reinforcement cage out of welded Grade 60 mesh that could be worked with hand tools. This allowed snug fitting of the mesh around utilities, storm water lines and other culvert breaches within the existing walls. Depth gauges were anchored to the substrate to verify the minimum 5-in. thickness specified for the new culvert walls. Multiple layers were applied along with hand troweling to ensure that material would be worked into the tight spots. Grout test cube samplings were collected daily for quality assurance, along with regular visual inspection of the depth gauges. Seven days after project completion, the cube testing already exceeded the 7,000 PSI anticipated lab results, while down below ground, all appears to be well still: No signs of shrinkage are visible, and the culvert remains smooth and watertight.

An ‘Excellent Alternative’

Hogue said that the completed project was a success. “I can’t speak for FDOT, but based on this project, and considering timeliness and relative simplicity when compared to replacement, this looks like an excellent alternative,” he said.

The total project took less than three weeks to execute at approximately one-third the cost of what excavation and replacement would have been, saving the state a lot of money and hassle. “And there was no impact on traffic whatsoever,” Hogue added. “Drivers [were] largely unaware [that] the sub-contractor team was performing this revolutionary procedure below the roadway.”

In some ways, the culvert under State Road 64 was typical of U.S. infrastructure: very old, stressed beyond original design intent due to population growth, subject to several regulatory agencies and difficult to access and replace. Replacement would have been complicated by difficult access, social impact, traffic disruption and by the relative high cost of new construction. This method, on the other hand, employed innovative processes and materials for a trenchless renewal of a major culvert completed in record time. The added bonus was the huge savings for Florida’s tight budget.